Long gone are the days when destroying confidential documents or products needed to be done by hand and would take so much time and effort. Nowadays, you have whole companies dedicated to the absolute destruction of private documents as well as the processing and recycling of a variety of products and materials. The whole process is accomplished by heavy-duty shredding machines that are designed to reduce bulky, tough materials into shredded remains that are then ready for the next step in the processing and recycling phase. There are several types of shredding machines out there in this industry that are engineered to handle a variety of applications at different throughputs.

When it comes to eradicating confidential information, there’s no better way than using a mobile shredding truck. These types of shredding machines are designed to take in these documents and shred them down to a point where they are completely unrecognizable. The trucks are often equipped with cameras inside the hopper so that the clients can witness the destruction of the documents firsthand, gaining a greater sense of peace of mind. Some trucks may also feature a hard drive shredder for digital information, which is powerful enough to fully destroy a hard drive within seconds until the drive and all of its information are completely unretrievable. In this digital age, it is essential to have access to such a shredder.

For destroying other types of products besides documents, there are many different types of shredding machines available in this industry. These primary and secondary shredders are designed to work on bulky materials in large quantities. These materials can include tires, medical waste, wood, construction waste, industrial waste, metals, beverage containers, and much more. Shredders of this kind are engineered with the immense power to take in these materials and crush them down into smaller sizes, preparing them for the next processing step. Many of these shredders feature different throughputs, depending on the types of applications that they need to frequently handle.

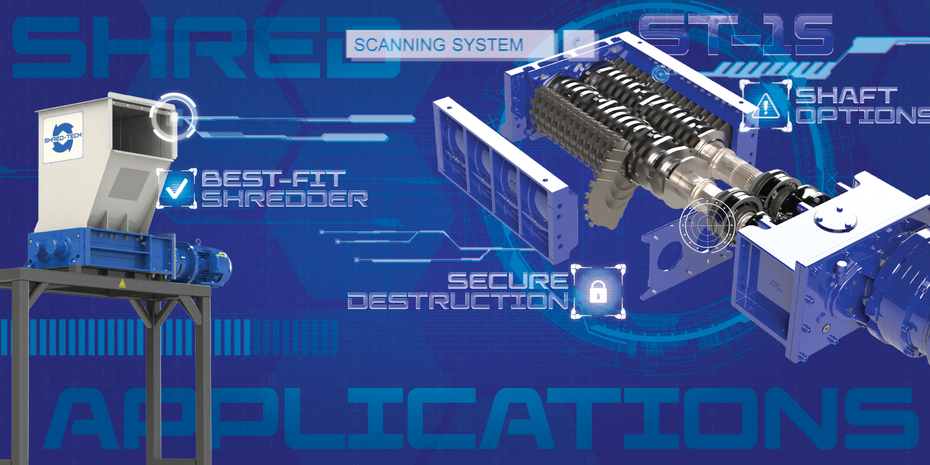

Applications

With just a push of a button, product destruction becomes quick and efficiently easy. Modern shredders can shred so much more with much greater effectiveness. From data tapes to circuit boards, from clothes to shoes, from credit cards to ID cards, from bricks to tires, there are so many different types of products that need to be shredded down for easier management. The right shredder needs to be used for the right application, whether it’s for hard drive shredding, waste processing, beverage container recycling, etc. When it comes to destroying products for protection, processing, or recycling, there are a number of powerful and high-performing shredding machines that can get the job done.

Beverage Container Recycling

Beverage bottling facilities often require a clean and cost-effective way to dispose out-of-date or out-of-spec bottled products. The right industrial shredder needs to be able to handle all shapes and sizes of cans, plastic bottles, and aseptic packaging. The tricky part with this type of application is that you are dealing with liquids as well as solids, so the shredder needs to be prepared to handle both elements. The ideal shredding solution is one that can destroy and separate liquid products from the solid aluminum or plastic packaging material, which will allow for maximum recycling and cost reduction. With an automated beverage container recycling system, it can easily process large boxes or totes of containers and liters at a significant throughput. The system separates the liquid from the packaging; the liquid is sent to a holding tank while the packaging is sent to a baler or other type of container. Beverage container recycling systems are essential for beverage container recycling.

Cardboard Recycling

Carboard shredding and recycling is a diverse application that is usually handled by a very niche company. The shredder needs to be able to handle single and bulky loads of mixed loose cardboard and paper. The configuration should include a cardstock, fine flute, and single and multi-wall corrugated of a variety of shapes and sizes. The cardboard system can be used for the destruction of out-of-spec packaging, which can increase in bulk density for reduced disposal costs while conditioning the product for further processing for the manufacture of construction insulation. There are several methods of material handling that can be utilized to make the process so much smoother, including conveyors and air-vey discharge.

Construction and Demolition

When it comes to handling the types of materials that are often overfilling the landfills, what can really get the job done is a highly efficient, high-powered slow-speed industrial shredding machine. Construction and demolition debris and materials are often large, bulky, and difficult to destroy using any standard shredder. These high-quality slow-speed shredders are built for industrial purposes. Their large frame and durable body allow them to handle the tougher materials with greater efficiency. They are designed for the initial shredding of a variety of materials, including biomass, paper, plastics, bulky waste, wood, organic waste, and more. For even better efficiency, these shredders can be mobile, allowing you to easily transport them to where the piles of debris are.

E-Waste Shredding & Recycling

The safe disposal of electronic waste once their useful life has been completed is a regulated issue. End-of-life (EOL) legislation for electronic waste is common throughout the world, and this requires manufactured custom systems to shred, separate, and recover the component materials that make up the electronic equipment. Items that need to be processed include notebooks, desktops, mainframes, telecommunication switching racks, military equipment, and more. These products are put through the shredding system where the system reduces and separates the component material, such as copper, steel, aluminum, plastic, and precious metals, allowing them to be recycled and repurposed. Customized shredding solutions are the ideal way to ensure that the post-consumer electronic products are effectively and economically recycled.

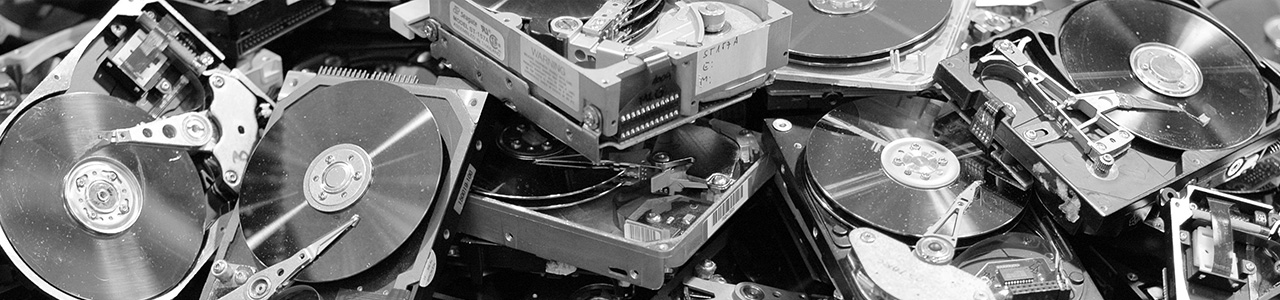

Hard Drive Shredding

Since we’re in a digital age, many companies store their important, confidential information onto hard drives. Because of this, hard drive destruction is one of the fastest growing segments in the information destruction industry. A specialized hard drive shredder is more than capable of eliminating both hard drives and solid state drives, ripping them into smaller pieces that are completely unrepairable, leaving the confidential information stored within them absolutely unretrievable. These types of shredding machines can come stationary or mobile. They can often be retrofitted onto mobile shredding trucks to give your business an extra stream of revenue in addition to shredding paper documents.

Medical Waste Processing

Many hospitals and high-volume commercial processing plants throughout the world utilize the power of a shredding machine to eliminate a variety of medical grade materials. These slow-speed, high-torque shredders usually process fabrics, glass, plastics, and stainless-steel instruments, among others. The powerful stationary shredders are designed to reduce bulky autoclaved waste destined for landfill by as much as 70%. Their strong and durable knives render those materials into a non-reusable and unrecognizable state.

Metals Shredding & Recycling

Some of the world’s largest primary and secondary metal recycling and processing facilities rely on high-torque industrial shredders to rip through the tough materials with ease and efficiency. What these facilities need are shredders that can handle applications that range from high-volume magnesium sprue and runner reduction at over 60 TPH to the reduction of titanium plate and sheet stock, which is one of the toughest applications known. In addition to these materials, the shredder also needs to be able to handle military and consumer electronics, telecommunications equipment, ACSR cable, baled aluminum, baled radiators, switching gears, and so much more. Specially designed hydraulic shredders can usually eliminate the need to guillotine materials prior to shredding, which will increase throughput while decreasing labor, handling, and maintenance costs.

Paper Shredding

The document destruction industry is a rapidly growing market that offers many lucrative business opportunities to start-up companies. All it requires is a strong and dependable shredder that can easily and effectively destroy your client’s confidential documents in a timely manner. For that, there are numerous shredders designed to accomplish such an important task. Commercial paper shredding systems along with mobile shredding trucks are capable of shredding massive loads of paper in under an hour. Their high-torque shear shredding technology ensures a high-security particle size that renders the documents completely destroyed and unrepairable. The ideal shredding solution is one that features low noise and dust generation, minimal maintenance, safe and easy operation, and bulk loading capabilities. Paper shredding systems need to be rugged, reliable, and highly efficient in order to provide the clients with essential peace of mind.

Plastics Shredding & Recycling

Reclaiming post-consumer and industrial plastic waste requires heavy-duty shredding models that feature dual or four-shaft configurations. These types of shredders can easily reduce purgings, film, engineered plastics, and large molded items, among others, so that they can be further granulated for reuse for molding or taken directly to extruding. Other shredding systems can be used to recycle post-consumer plastics into products like plastic lumber, be used to reclaim nylon from carpeting, and be used to reclaim packaging and prevent liability prior to disposal. The benefits of shredding plastic material include, but aren’t limited to, reduced capital costs, operating costs, material fines generation, and granulator downtime. The dual/four-shaft shredders have the power to achieve this with better efficiency.

Product Destruction & Recycling

Specialized and customized material separation and recovery/destruction systems are used around the world to destroy, recovery, and separate a variety of off-spec, mis-packaged, and outdated products. Such applications include recovering precious metals from computers and telecommunications scrap, nylon from carpets, and recyclables from MSW. Mis-packaged consumer products are separated for outward recycling, and off-spec consumer products are completely destroyed to provide manufactures with liability protection. These specialized shredding and recovery systems are designed to help eliminate the cost of disposal while generating revenue for the company. They have the technology and components required to destroy and recycle or safely dispose of most consumer products.

Tire Shredding & Recycling

There is an increasing demand for tire processing equipment that is designed for the effective reduction and recovery of scrap tires. The number of discarded tires continues to increase, overtaking landfill capacity and causing negative impacts on the environment, so the scrap tire processing industry is looking for high-torque tire shredders and systems that range from 80 to 1,200 HP (60 to 900 kW) and are capable of processing automobile, truck, and off-road tires at rates in excess of 20 tons per hour. These types of industrial shredding machines can be electric or hydraulic as well as stationary for plant-based operations or mobile for on-site shredding capability. Shred-Tech tire shredding systems include both infeed and outfeed conveyors and classifiers designed for ensuring 2” minus absolute sizing, and each durable and cost-effective shredder delivers high knife tip cutting force with convenient equipment to service and maintain.

Waste Processing

Waste processing systems are the versatile shredding machines that are capable of destroying hazardous, medical, municipal, industrial, commercial, and construction waste. What you really need to accomplish this is a high-quality system that is designed to meet regulatory safety and material handling requirements while also effectively shredding through some of the toughest materials that are often found in a landfill. Customized shredding solutions are often required to handle each unique waste handling and processing challenge. Shredding companies like Shred-Tech® can engineer a specialized system to meet the specific application requirements, offering options such as automated material handling, nitrogen blanketing, explosion proofing, sterilization systems, and screening equipment.

US Dollars

US Dollars