Shred-Tech ST-480 Industrial Shredder

- Heavy-duty applications

- Fed manually or by conveyor

- Bin Tipper

- Drive options between 100HP-300HP

Shred-Tech ST-480 Industrial Shredder

Applications

The ST-480 Industrial Shredder can be used for the following applications:

- Aluminum Recycling

- Battery Recycling

- Alkaline Battery Recycling

- EV Battery Recycling

- Lead Acid Battery Recycling

- Lithium Ion Battery Recycling

- Nickel Cadmium Battery Recycling

- E-Waste Recycling

- General Waste Recycling

- Green Waste Disposal & Recycling

- Medical Waste Recycling

- Metal Recycling

- MSW Shredding

- Pallet Recycling

- Paper Shredding

- Plastic Recycling

- Textiles & Carpet Recycling

- Tire Recycling

- Wood Recycling

Standard Features for the ST-480

There are a number of high-quality standard features that are included with the ST-480 Industrial Shredder. Each component is engineered to provide reliable support to the rest of the shredding system, ensuring that the machine is operating at maximum capacity. In addition to easily removeable sectional cleaning fingers and a lightweight chamber plate designed for quick cutting chamber disassembly, the shredder machine also features highly sharp knives, durable hex shafts, and easy-to-use control panel.

Knives

Superior durability and higher serviceability is evident when you take a look at the heavy-duty knives that take up our entire cutting chamber. These knives are built with a sharp tip that is more than capable of piercing right into the product, biting down hard, and ripping it apart until there’s nothing leftover but scraps. Each knife profile and configuration are designed by our engineers to suit the application, allowing for maximized throughput and optimized shred size. These knives are tough enough to rip through steel, wood, metal, and so much more.

Hex Shafts

The machined hex shafts are uniquely designed to offer maximum knife placement options so that you can easily configure the shredder machine to suit your application. It is also designed for much easier knife removal and machine maintenance. Size for size, our hex shaft is engineered to be several times stronger than a keyed shaft. It has the durability needed to withstand the constant demands of the industry. Its hex shaft drive system is designed by our Shred-Tech® engineers to offer you the highest knife-tip cutting force of any comparable shredder on the market.

Control Panel

For optimized control over the entire shredding process, we made sure to include the high-quality control panel with the ST-480 Industrial Shredder. This is a sophisticated system that is designed and fabricated by qualified Shred-Tech® technicians. It allows you to stay in full control over the shredder machine. It also comes with a wide range of easy-to-use and supportive features, which include hour meter, keyed power switch, illuminated function buttons, fused lockable disconnect, and a programmable logic controller for basic shredder functions, including knife reversal on overload.

* Established at time of order

Optional Accessories for the ST-480

Shred-Tech® has an array of high-quality operational accessories available for our ST-480 Industrial Shredder. Each of these components is designed to provide unrelenting support to the entire shredding system, making the job easier and more efficient for your workers. Among others, we have the hopper, in-feed and out-feed conveyor, and stand available to improve the performance of the industrial shredder. The Shred-Tech® sales team is on standby 24/7 to provide you with more information on the variety of optional accessories we have available so that you can design and create the ideal shredder that suits your applications.

Hopper

In order to experience superior workmanship, you can get the high-quality hopper for the ST-400 Industrial Shredder. Built to work flawlessly with the rest of the shredding system, the hopper is designed to be wide enough to accept a variety of products, including heavy drums, truck tires, industrial waste, and so much more. For superior quality, our engineers have ensured that the hopper is extra durable so that it can withstand the constant demands of the rougher materials.

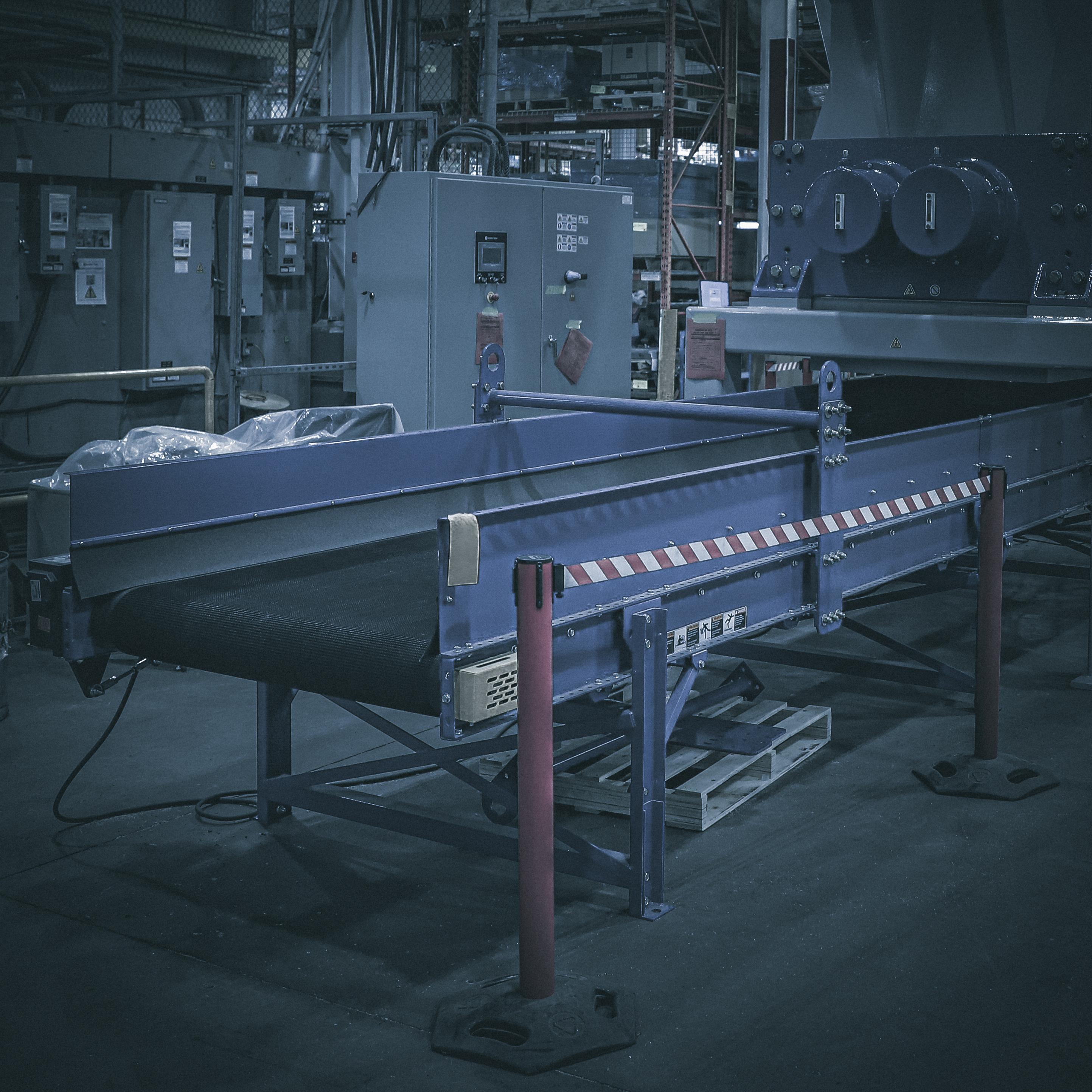

In-Feed & Out-Feed Conveyor

Designed to make the job so much more convenient for your workers, the in-feed conveyor and out-feed conveyor work flawlessly with the rest of the shredder machine. These reliable components work together to keep the workflow moving smoothly with minimal to no interruptions. The in-feed conveyor moves the materials directly into the shredder while keeping your workers away from the blades. The out-feed conveyor then transfers the shredded remains away from the machine for easier management.

Stand

A heavy and large machine such as the ST-400 Industrial Shredder can greatly benefit from the addition of a stand. This high-quality stand is built with the heavy-duty strength to support the entire shredder machine. It has the durability to withstand the challenge, bringing extra stability and support to the job.

US Dollars

US Dollars