Shred-Tech ST-75 Industrial Shredder

- Car Parts, Steel Drums, Plastic Drums, Skids, Fabrics, Steel & Aluminum Stampings, Trim Scrap, Electronics, Pallets, Wood, Hazardous Waste, Sharps, Medical Waste, Data Tapes, Documents, Paper, Metals, Plastics

- Medium/Heavy-duty applications available in three chamber sizes

- Fed manually or by conveyor

- Bin Tipper

- Drive options between 30HP-120HP

Shred-Tech ST-75 Industrial Shredder

Shred-Tech® can meet your requirements and surpass your expectations with our high-performing ST-75 Industrial Shredder. This heavy-duty shredder machine has the much-needed strength to rip through bulky and tough materials as if they were made of butter. It is a powerful but cost-effective machine that can help you and your business outperform your competitors in this growing industry. It combines high performance with great versatility, culminating in a superior industrial shredder that is perfect for established businesses looking to expand and scale their operations.

The ST-75 Industrial Shredder features a 25” wide chamber with three available lengths. The shredder is capable of tearing through many solid products, such as steel drums, plastic drums, fabrics, steel and aluminum stampings, high-volume confidential waste, and more. It offers a medium-duty throughput, allowing you to shred through your items at an increasingly efficient rate. The industrial shredder is designed to help decrease your business’s footprint while offering greater opportunities for your company to expand into new segments while broadening your customer base. The bulkhead walls and labyrinth barriers are positioned at each end of the cutting chamber for effective protection for the bearing and seal. Replacement for the bearing and seal can be easily done so maintenance and repairs are always fast and simple.

Applications

The ST-75 Industrial Shredder can be used for the following applications:

- Aluminum Recycling

- Battery Recycling

- Alkaline Battery Recycling

- EV Battery Recycling

- Lead Acid Battery Recycling

- Lithium Ion Battery Recycling

- Nickel Cadmium Battery Recycling

- E-Waste Recycling

- General Waste Recycling

- Medical Waste Recycling

- Metal Recycling

- Paper Shredding

- Plastic Recycling

- Textiles & Carpet Recycling

- Wood Recycling

Standard Features for the ST-75

Our ST-75 Industrial Shredder is engineered by experts to outperform in this industry, and it comes with a variety of standard accessories that enhance its overall performance. Its cast aluminum body design combines with an increase in shaft hex thickness, knife diameter, and spacer thickness to create a high-quality machine that is superior in durability with higher service factors. It also features easily removable sectional cleaning fingers and a lightweight chamber plate for quicker and easier cutting chamber disassembly. Each of these components works effectively together to provide you with an industrial shredder that is high in serviceability for better ROI.

Knives

For optimal cutting capabilities, the ST-75 Industrial Shredder is equipped with several highly destructive knives. Each knife profile and configuration has been carefully designed by our engineers to meet the application for optimized throughput and maximum shred size. Offering superior cutting strength, the knives work flawlessly together to slice right through thick material until only scraps remain. Their sharp and durable frames and biting tips can eat through products with both ease and efficiency.

Hex Shafts

The hex shaft is uniquely designed to maximize knife placement options so that you experience optimized shredding use for a wide variety of applications. The hex shaft works together with the knives to guarantee maximum shred size on the materials. The shaft is easy to access for easier knife removal and machine maintenance. It is several times stronger than a keyed shaft, and maximizes the knife-tip cutting force.

Control Panel

The ST-75 control panel is designed by Shred-Tech® engineers and built in house by our certified technicians. It features a large screen HMI, a keyed power switch, fused lockable disconnect, an hour meter, and a programmable logic controller for shredder functions, including automatic overload detection and knife reversal. This panel puts the entire shredding process right into your hands, allowing you to take full control to ensure that the system is working just how you want.

* Established at time of order

Optional Accessories for the ST-75

We offer many optional accessories for the ST-75 Industrial Shredder that work to not only improve the performance of the machine but also make the job easier for operators. Among others, we have the durable hopper, the convenient in-feed conveyor and out-feed conveyor, and the stabilizing stand. These options allow you to configure the shredder to fully meet your requirements. For even more optional accessories and information on how Shred-Tech® can work with you to create the ideal solution to suit your specific application or requirements, contact our expert team today.

Hopper

You get to experience high-quality workmanship if you choose to include the hopper with your ST-75 Industrial Shredder. This is a heavy-duty piece of equipment that can help make the loading process easier thanks to its funnel-like design. The hopper can be configured to match the application or the installation, bringing you an extra level of equipment versatility to make the shredding process more manageable.Speak to your local sales rep about your specific needs, including dust extraction, safety curtains, and infeed locations. Speak to your local sales rep about your specific needs, including dust extraction, safety curtains, and infeed locations.

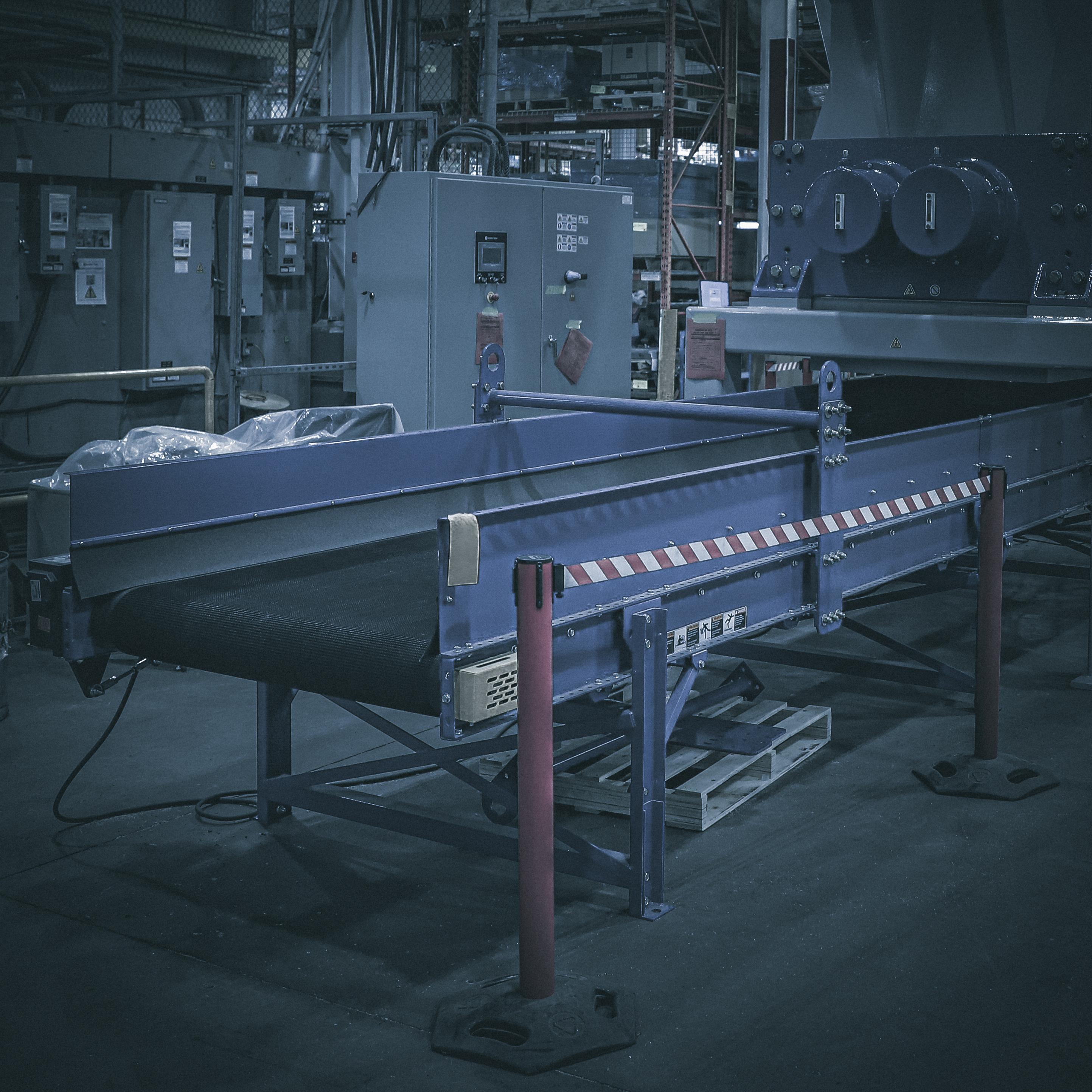

In-Feed & Out-Feed Conveyor

For increased convenience, we recommend you get the in-feed conveyor, the out-feed conveyor, or both for your ST-75 Industrial Shredder. These systems are designed to make transporting the materials to the shredder easier and more efficient by automating the loading and unloading processes. The in-feed conveyor transfers whole materials directly into the shredder, keeping workers a safer distance away while the out-feed conveyor transports the shredded remains of the materials away and into a bin or baler for collection and further processing or use. These conveyors can help keep the workflow moving smoothly so that you can keep up with the constant demands of the industry.

Stand

One of the best ways to increase stability for your ST-75 Industrial Shredder is to include a custom stand. This is a high-quality stand that is engineered with an emphasis on durability to easily support the weight of the entire shredder machine, offering greater stability and security for the job. Adding a stand also permits greater clearance in your facility space for the use of peripheral equipment, such as an out-feed conveyer; shredded material can fall via gravity from the shredder, which is then transported via downstream equipment. The stand can come fully enclosed with a safety interlocking door and emergency stop button.

US Dollars

US Dollars