Shred-Tech STQ-75 Industrial Shredder

- Light Automotive Scrap, Plastic Drums, Skids, Fabrics, Thin Gauge Steel & Aluminum Stampings, Trim Scrap, Electronics, Pallets, Wood, Hazardous Waste, Sharps, Medical Waste, Data Tapes, Documents, Paper, Thin Gauge Metals, Plastics

- Medium-duty applications with three cutting chamber sizes

- Fed manually or byconveyor

- Bin Tipper

- Drive options between 60HP-80HP

Shred-Tech STQ-75 Industrial Shredder

The super-tough STQ-75 Industrial Shredder from Shred-Tech® is an excellent choice for shredding and recycling companies focused on improving workflow efficiency, lowering operating costs, and obtaining a high ROI on high-quality equipment. This shredder is designed to process bulk materials including wood, plastics, textiles, electronic equipment, medical waste, organic waste, manufactured products, and various other materials, reducing them to a uniform particle size using its quad-shaft design. It does more so you can do more! The STQ-75 has been engineered to optimize high-volume shredding for its size and offers an impressive average throughput across all material types. By utilizing the heavy-duty construction, high power, and swift operation of the STQ-75, you can effectively reduce your footprint while increasing productivity for improved revenue.

At Shred-Tech®, we’re known for putting quality, efficiency, and usability at the forefront of our design philosophy, and the STQ-75 is no exception. It comes with a 35” wide chamber available in various lengths, this industrial shredder machine thoroughly destroys the fed material. With Shred-Tech® equipment, not only do you get powerful equipment, but also a dedicated team of experts ready to assist you with maintenance, repairs, parts replacement, financing, and more! Your purchase of an STQ-75 Industrial Shredder also comes with a 1-year or 2,000-hour warranty to protect your investment.

Applications

The STQ-75 Industrial Shredder can be used for the following applications:

- Aluminum Recycling

- Battery Recycling

- Alkaline Battery Recycling

- EV Battery Recycling

- Lead Acid Battery Recycling

- Lithium Ion Battery Recycling

- Nickel Cadmium Battery Recycling

- E-Waste Recycling

- General Waste Recycling

- Green Waste Disposal & Recycling

- Medical Waste Recycling

- Metal Recycling

- Paper Shredding

- Plastic Recycling

- Textiles & Carpet Recycling

- Wood Recycling

Standard Features for the STQ-75

Shred-Tech® has equipped the STQ-75 Industrial Shredder with an abundance of standard features that all combine to help create a powerful, efficient, and easy-to-use shredding solution you can depend on for years to come. Featuring a sturdy and easy-to-maintain construction, super-sharp cutting chamber knives, durable hex shafts, and a convenient rollout screen design, this shredder machine has the high-performance capabilities required to handle daily industrial shredding applications.

Construction

Heavy-duty construction based around Shred-Tech®’s standard torsion tube body concept ensures robust, trouble-free operation of the STQ-75. Our proprietary triple seal cutting chamber, abrasion-resistant wear components, and exceptionally high knife tip cutting force ensure low noise and vibration, reduced wear, and decreased maintenance costs.

In fact, maintenance of the STQ-75 is further enhanced thanks to simplified modular construction, which reduces the number of major components and increases parts commonality, thus reducing spare parts requirements. Bulkhead walls and labyrinth barriers at either end of the cutting chamber provide excellent bearing and seal protection, while a lightweight chamber plate ensures cutting chamber disassembly is quick and easy.

Knives

In order to allow for optimal and thorough destruction of all applicable materials fed into the shredder, the STQ-75 boasts heavy-duty shredding knives. Each knife has been engineered and manufactured sharp to permit high throughput and produce the smallest possible scrap particles to maximize efficiency. The shredder can be customized with a variety of knife thicknesses to suit your application.

Control Panel

The STQ-75 control panel is designed by Shred-Tech® engineers and built in house by our certified technicians. It features a large screen HMI, a keyed power switch, fused lockable disconnect, an hour meter, and a programmable logic controller for shredder functions, including automatic overload detection and knife reversal. This panel puts the entire shredding process right into your hands, allowing you to take full control to ensure that the system is working just how you want.

* Established at time of order

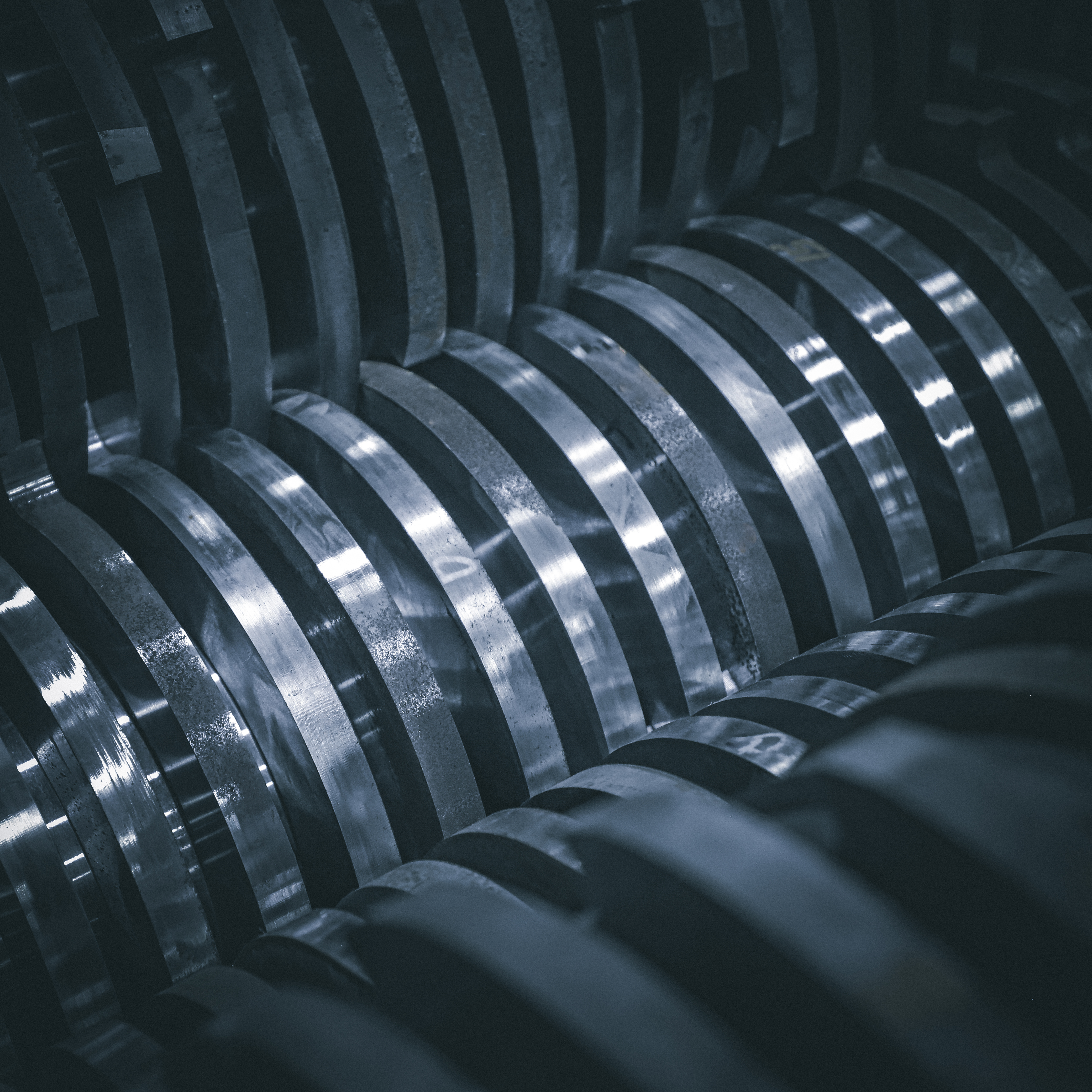

Hex Shafts

Shred-Tech®’s standard durable hex shafts and robust drive systems are at the heart of the STQ line of shredders, ensuring years of reliable service. Engineers have focused a high degree of attention on building a line of four shaft shredders that are maintenance-friendly and allow for quick and easy component changes. Thanks to a carefully engineered design, the hex shafts on the STQ-75 provide the highest knife-tip cutting force of any comparable industrial shredder available.

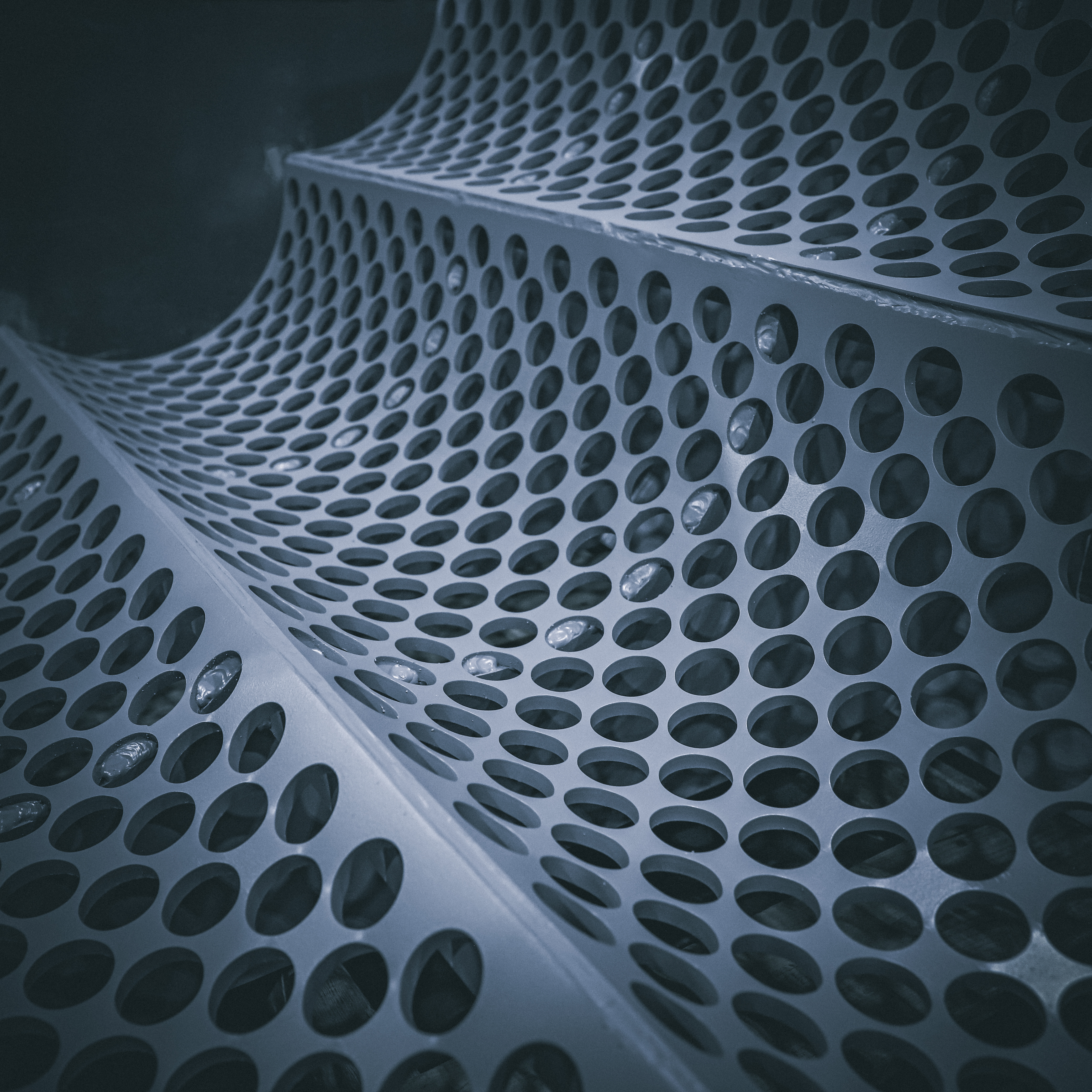

Rollout Screen

Shred-Tech® focused on ease of use and high productivity when designing the STQ-75 Industrial Shredder to make it an excellent choice for lowering operating costs and driving profits, and that level of focus and care even goes down to the shredder’s rollout screens. Rollout screens on the STQ-75 are easily removed from the end of the shredder. This allows for quick and easy screen cleaning as well as the ability to efficiently swap out the screens for alternate sizes.

Optional Accessories for the STQ-75

If the standard features of the STQ-75 Industrial Shredder don’t exactly match your requirements, or if you’re looking for a shredder that’s outfitted with even more quality-of-life enhancements, efficiency, and durability, then you can choose from a list of excellent optional accessories. Whether you require complete equipment integration, conveyors, separating components, or more, Shred-Tech® has got your back. If the list of options here still doesn’t meet your requirements, get in contact with us today and we’d be glad to help you design a custom shredding solution that perfectly meets your application and can drive your business forward for years!

Stands and Hoppers

Adding custom stands can help you raise the shredder off the ground to create plenty of clearance for shredded material to drop via gravity into a container or onto downstream equipment like a conveyor. This can be great for facilities looking to streamline the entire shredding process. Custom hoppers can be easily added to the STQ-75 to create smoother in-feeding via a conveyor or other peripheral equipment. This option can help you make the most efficient use of your facility space and ensure consistent in-feeding of material to the shredder while preventing buildup or blockage. peak to your local sales rep about your specific needs, including dust extraction, safety curtains, and infeed locations.

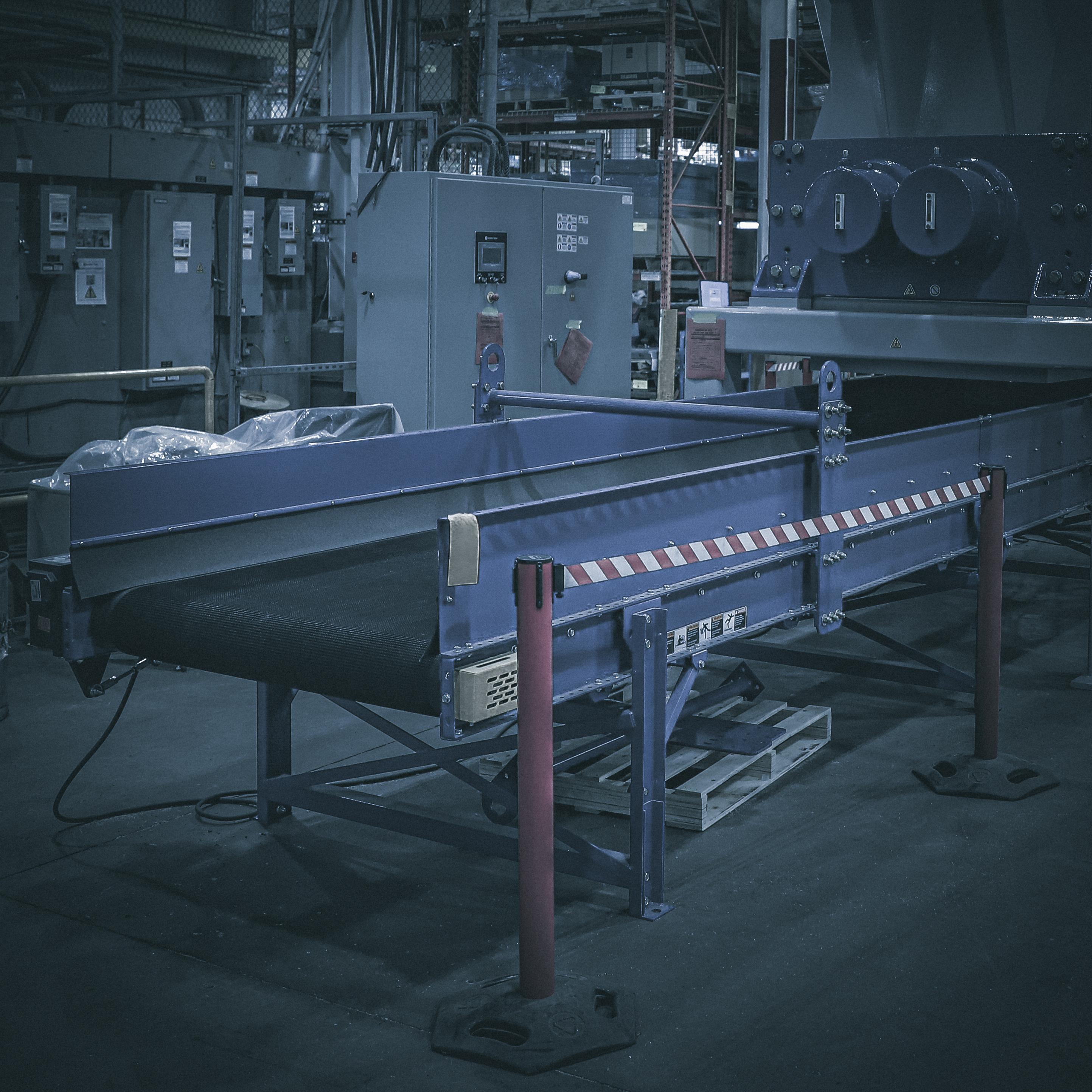

In-Feed and Out-Feed Conveyors

To create a high level of efficiency and smooth operation while allowing the maximum amount of material into the shredder, you can opt for an in-feed conveyor, out-feed conveyor, or both. Adding one or both can dramatically improve the speed and ease by which operators shred material at your facility. By automating the loading and unloading process with conveyors, you can increase both productivity and revenue.

US Dollars

US Dollars